- Search:

Production Mold

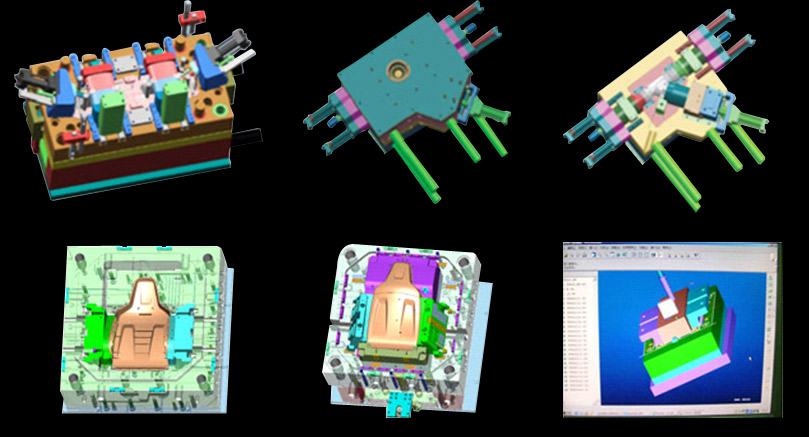

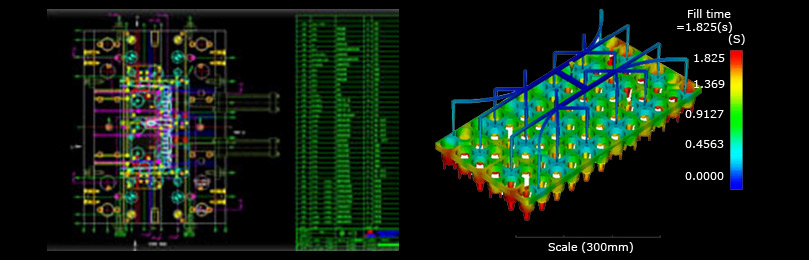

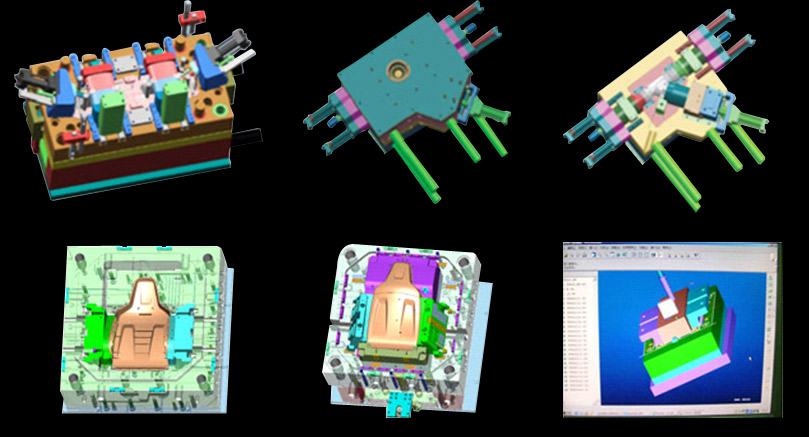

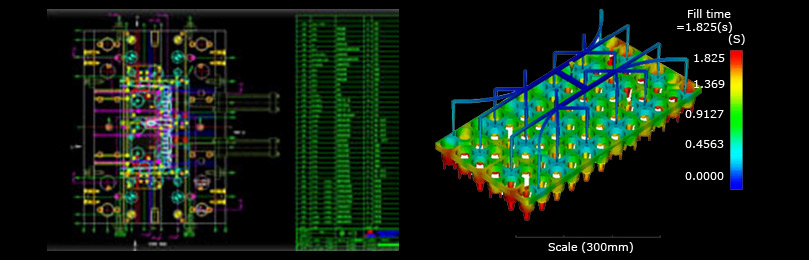

Practical, efficient and economical is the highest policy of our mold design and manufacturing. The mold flow software to simulate resin flow help to offer the best solution, the standard mold module database of UG &PRO / E software do good to formulate the mold layout quickly, and by the Mastercam CAM software to the NC processing data to ensure consistency.

Our design and technical staff team are experienced staffs, most of whom have been serving for the well-known mould companies more than 10 years doing research & development, mould design &manufacturing and production work. Therefore they are very familiar with all kinds of plastic, metal and casting material properties and processing technology. They devote themselves to manufacture high quality molds and moldings to pay back the continuant trust from our customers.

By using the updated technology software available, our capability is able to take your project from the spark of an idea to prototyping and onto full production. Our Designer can skillfully and flexibly use a variety of CAD formats, such as:

◆ Pro/ENGINEER (3D Modeling)

◆ SolidWorks (3D Modeling)

◆ AutoCAD (2D Modeling)

◆ MoldFlow Mold Advisor (Plastic flow/deform simulation)

◆ MasterCAM (CNC Programming)

◆ Unigraphics (CNC Programming)

We can provide different mold standard and mould design as our customer's requirement. Skilled engineers makes all designs easy to get approved by clients. We are also experienced in designing and making hot runner molds and 2-shot mold. The popular hot runner brands are: Hasco, Husky, Incoe, Mold master, Mastip, DME, YUDO, Synventive and so on.

Many kinds of world-wide applied mould steels are used in our production. And our moulds are major for USA and Europe market. Most mould bases and standard components come from LKM. At the same time, we also can design mould according to customer's requirement, such as DME, HASCO standard. Below are some information for your reference.

Our design and technical staff team are experienced staffs, most of whom have been serving for the well-known mould companies more than 10 years doing research & development, mould design &manufacturing and production work. Therefore they are very familiar with all kinds of plastic, metal and casting material properties and processing technology. They devote themselves to manufacture high quality molds and moldings to pay back the continuant trust from our customers.

By using the updated technology software available, our capability is able to take your project from the spark of an idea to prototyping and onto full production. Our Designer can skillfully and flexibly use a variety of CAD formats, such as:

◆ Pro/ENGINEER (3D Modeling)

◆ SolidWorks (3D Modeling)

◆ AutoCAD (2D Modeling)

◆ MoldFlow Mold Advisor (Plastic flow/deform simulation)

◆ MasterCAM (CNC Programming)

◆ Unigraphics (CNC Programming)

We can provide different mold standard and mould design as our customer's requirement. Skilled engineers makes all designs easy to get approved by clients. We are also experienced in designing and making hot runner molds and 2-shot mold. The popular hot runner brands are: Hasco, Husky, Incoe, Mold master, Mastip, DME, YUDO, Synventive and so on.

Many kinds of world-wide applied mould steels are used in our production. And our moulds are major for USA and Europe market. Most mould bases and standard components come from LKM. At the same time, we also can design mould according to customer's requirement, such as DME, HASCO standard. Below are some information for your reference.

Add: No.118 ChangAn zhong Road ,ChangAn Zhongxin Industrial Park,ChangAn Town,Dongguan City,Guangdong,China

Power by DedeCms

Tel:0086-769-87015606 Fax:0086-769-82586051